Portable Intermittent Fault Detector™

(PIFD-512™)

AWTS Interface Test Adapter & WATT 1 Pylon Wire Harness

Test Summary

Introduction:

The Universal Synaptics (USC) Team performed Portable Intermittent Fault Detector™ (PIFD™) testing on the AWTS Interface Test Adaptor cable and the WATT 1 F/A-18 Pylon wiring harness at REDACTED utilizing the following equipment:

- Portable Intermittent Fault Detector™ (PIFD™) – test was conducted with a 512 test point version of the PIFD

- USC-PIFD-00512

- NSN:6625-01-696-1235

- Two PIFD AWTS patch cable Interface Test Adapters (ITAs) to electrically connect the PIFD to the AWTS ITA and the WATT 1 wiring harness

- Handheld vibration tool to stimulate the wiring harnesses during PIFD testing

Location:

- NAS REDACTED Fleet Readiness Center REDACTED

Background:

Maintenance leadership and artisans at FRCW seek advanced maintenance and sustainment technology solutions to reduce can-not-duplicate (CND / A799) test results in wiring systems, decrease maintenance turnaround times (TAT), and reduce costs associated with test program set (TPS) development.

Leadership at REDACTED selected the AWTS interface test adapter for the WATT 1 and the WATT 1 F/A-18 Pylon wiring harness for this PIFD technology demonstration. It was noted that the “good” AWTS interface cable exhibits “ghost faults” during AWTS testing. Undetected and hence unrepaired intermittent failures have many names across maintenance and sustainment communities (No Fault Found (NFF), No Evidence of Failure (NEOF), Cannot Duplicate (CND), A-799, “gremlins” and “ghost faults”).

Conventional single-circuit sampling Digital Multi-Meters (DMMs) and conventional single-circuit serial scanning test equipment and troubleshooting methods have been proven by the Department of Defense (DoD) to be insufficient to remediate or reduce CND / A-799 in aircraft wiring systems.

The PIFD is purpose-built to detect and isolate intermittent failures which are conclusively linked as the prime driver of high CND / A-799 and NFF test results in wiring systems and sub-systems. The goal of this demonstration effort was to validate the utilization of the PIFD to detect and isolate intermittent faults that conventional AWTS and AWTS-type testers are unable to detect or isolate. Reduce CND / A-799 test results, increase the time-on-wing of aircraft wiring systems, and demonstrate the advanced capabilities of AutoMap™. The PIFD is the only objectively proven test capability to reliably detect and isolate intermittent faults in compliance with DoD MIL-PRF-32516.

PIFD testing was conducted on one (1) AWTS interface cable and one (1) WATT 1 wiring harness. No maintenance or test data was provided, and no Test Program Set (TPS) was developed before on-site arrival on 05 March 2025 to demonstrate the PIFDs AutoMap™ automatic TPS generation capability, ease of use with minimal training, and advanced intermittent fault detection and isolation diagnostic capability.

PIFD Test Functions:

- AutoMap™ – discovers the as-wired configuration without the need for wiring schematics or OEM data

- Continuity – tests for open circuits and measured resistance against established AutoMap baseline (open circuits / high resistance tests)

- Shorts – provides shorted circuit indications and shorts tracing

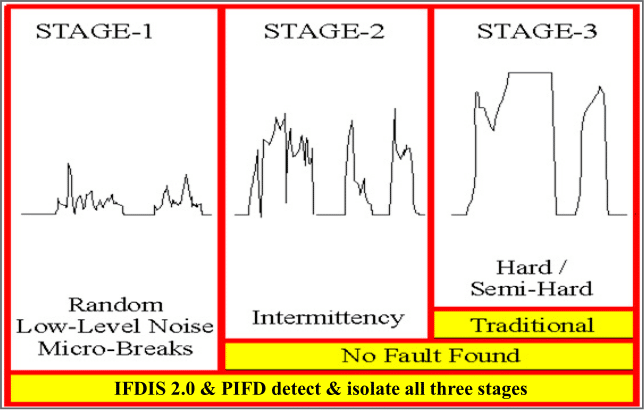

- Intermittence – monitors all circuits simultaneously and continuously to detect and isolate all Three Stages of an Intermittent Fault (Graphic 1) in compliance with DoD MIL-PRF-32516

- Fault Isolation – root cause determination of detected intermittent faults through programmatic isolation

Graphic 1 – Three Stages of an Intermittent Fault

Stage 1 – random low-level nanosecond microbreaks, likely not operationally evident yet, but on curve of degradation to become Stage 2

Stage 2 – intermittent failure evident to pilot in operation, reported to ground crew, passes ground test and labeled No Trouble Found (NTF) or No Fault Found (NFF), on curve of degradation to become Stage 3

Stage 3 – semi-hard or hard failures, Automatic Test Equipment (ATE) and troubleshooting tools such as DMMs designed to detect hard faults (open circuits or shorted circuits)

Test Procedures:

- AutoMap™ – discovers the as-wired configuration of the unit under test (UUT)

- Continuity – tests for open circuits and measures resistance against established AutoMap baseline (open circuits / high resistance tests)

- Shorts – provides shorts indication and shorts tracing

- Intermittence – monitors all circuits simultaneously and continuously to detect and isolate intermittent faults

- Fault Isolation – programmatic isolation of detected intermittent faults

Portable Intermittent Fault Detector™ (PIFD™), NSN: 6625-01-696-1235

Results: AWTS Interface Cable

Test #1:

- Automap discovered the as-wired configuration of the AWTS interface cable. The AWTS interface cable had 95 wired connections and 89 Node groups. This step took approximately seven minutes for AutoMap to complete. No pre-programmed information was entered into the PIFD. AutoMap demonstrated the time savings provided by utilizing AutoMap artificial intelligence and machine learning automatic test program set (TPS) generation process.

- Continuity testing conducted – no open circuits present in the AWTS interface cable.

- Shorts testing conducted – no short circuits were present in the AWTS interface cable.

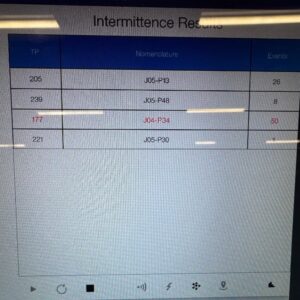

- Intermittence testing conducted – light vibration was applied via a handheld vibration tool. Intermittent faults were detected and isolated:

– J04-P35 – 50 intermittent events detected and isolated

– J05-P13 – 26 intermittent events detected and isolated

– J05-P48 – eight (8) intermittent events detected and isolated

– J05-P30 – one (1) intermittent event detected and isolated

PIFD Intermittence Results Screen of AWTS interface cable test

Results: AWTS Interface Cable

Test #2:

- Automap discovered the as-wired configuration. The WATT 1 wiring harness had 89 wired connections and 44 Node groups. This step took approximately six minutes for AutoMap to complete. No pre-programmed information was entered into the PIFD. AutoMap demonstrated the time savings provided by utilizing AutoMap artificial intelligence, and machine learning automatic test program set (TPS) generation process.

- Continuity testing conducted – no open circuits present in the WATT 1 wiring harness.

- Shorts testing conducted – no short circuits were present in the WATT 1 wiring harness.

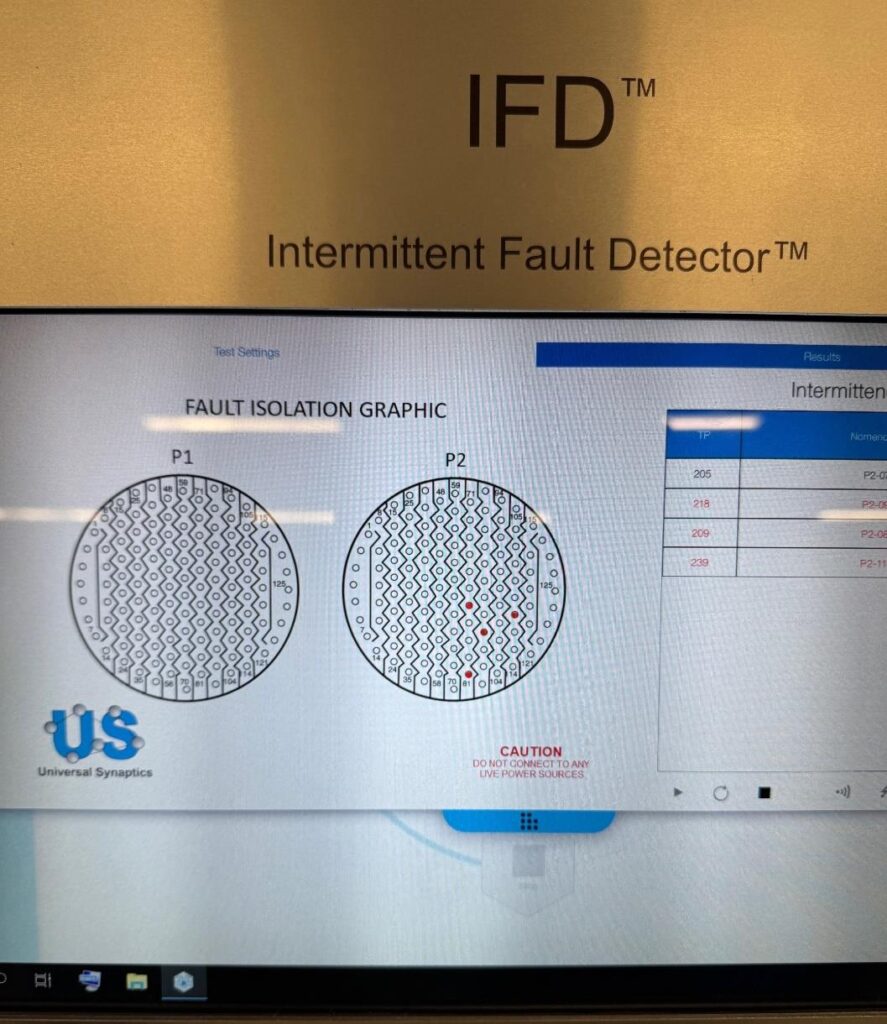

- Intermittence testing conducted – light vibration was applied via a handheld vibration tool Intermittent faults were detected and isolated:

– P2-090 – 50 intermittent events detected and isolated

– P2-081 – 50 intermittent events detected and isolated

– P2-111 – 50 intermittent events detected and isolated

– P2-077 – 26 intermittent events detected and isolated

– intermittent faults in the AWTS interface cable were also detected and isolated

PIFD Fault Isolation Graphic of the WATT 1 F/A-18 Pylon Wiring Harness

Observations:

- Conventional single-circuit scanning test sets, digital multi-meters, and functional ATE are not designed to find intermittent faults that are consistently detected and isolated by the PIFD resulting in a $5.5 billion a year problem for the DoD.

- The REDACTED and USC teams’ collaboration and focus on advanced test technology applications to reduce CND / A-799 test results through intermittent fault detection and isolation contributed to the overall success of the PIFD technology demonstration on the AWTS interface cables and WATT 1 wiring harness.

- The entire test project was accomplished in one hour.

Summary:

The reliable electronic functionality of the F/A-18 is required to ensure the survivability and lethality of the F/A-18 weapon system. Equally important is the reliable functionality of test systems and interface cables that connect test systems to the respective weapon system wiring harnesses. Intermittent test set cables render test results erroneous as the maintenance professionals tasked with ensuring weapon system readiness are unable to decipher if the “ghost faults” are due to intermittent test cables, intermittent weapon system wiring, or both. Proven advanced test technology, such as the PIFD is required to ensure weapon system readiness, quick and comprehensive maintenance outcomes, and root cause failure analysis and repair. The PIFD has been exhaustively studied by the Services for nearly two decades, it has been objectively proven in multiple maintenance domains across every major Department of Defense (DoD) weapon system.

The Beyond Capable Maintenance Interdiction (BMCI) team of artisans at REDACTED has effectively increased the reliability of the F/A-18 Generator Converter Unit (GCU). The BMCI team at REDACTED has utilized the Intermittent Fault Detection & Isolation System™ (IFDIS™) to remediate intermittent / CND issues in the F/A-18 GCU and increase time-on-wing by 400% (source: GAO-20-116).

The PIFD leverages the same advanced, proven technology contained in the IFDIS. The BCMI artisans were able to locate and repair 73 wiring harnesses with the IFDIS. Fifty-eight of the 73 GCU harnesses passed the Aircraft Engine Component Test Stand (AECTS) functional test bench. Many of them were “Bad Actors” with low time-on-wing. Without the BCMI team’s utilization of advanced, proven, Intermittent Fault Detection technology (IFDIS and PIFD), these wiring systems would have made it back into the Navy supply system and worse back on the F/A-18 only to repeat the operational failures that had the wiring harnesses removed and sent to REDACTED.

Universal Synaptics’ patented Intermittent Fault Detection technology has been proven to increase aircraft availability and reliability. As proven by this demonstration, the PIFD once implemented will increase the reliability of the wiring assemblies it is applied to by ensuring open circuits, shorted circuits, and intermittent circuits are rapidly identified and repaired, breaking the cycle of CND / A-799, No Fault Found, and “ghost fault” test results. The PIFD is wholly agnostic and can be utilized on any Navy weapon system. Reductions in CND / A-799, root cause failure data, and accurate repair have been proven to significantly increase aircraft readiness, survivability, and lethality in every instance where the PIFD has been applied.