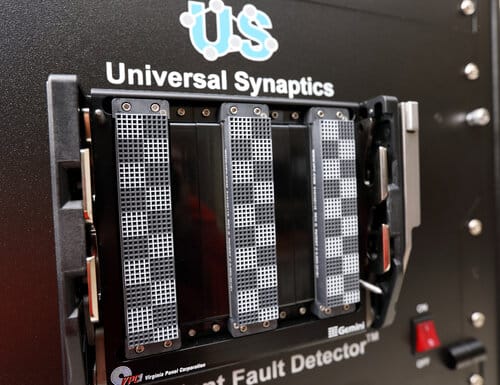

INTERMITTENT FAULT DETECTION & ISOLATION SYSTEM 2.0

IFD-5120 Single Rack pictured

(Patented with Additional U.S. and Foreign Patents Pending)

IFD-5120 Rack pictured with Environmental Chamber, Vibration Table, and Interface Test Adapter (ITA) Rack

IFDIS and IFDIS 2.0 Standard Front Panel Connector

Intermittent Fault Detection & Isolation System 2.0™ (IFDIS 2.0™)

IFDIS 2.0 is a patented diagnostic instrument that can simultaneously and continuously monitor all unit under test (UUT) circuits, individually at the same time, detecting intermittent faults that occur, even as short as *50 nanoseconds (0.00000005 seconds) in duration. IFDIS 2.0 is modular Automatic Test Equipment and capable of interfacing to components in increments of 1,280 electrical connection points.

In addition to detecting and isolating intermittent faults, the IFDIS 2.0 AutoMap feature will automatically interrogate and store the as-designed wiring configuration for a good unit and then based on that “gold” configuration, detect any open, short, ohmic, impedance, drift or mis-wiring problems in subsequent UUTs.

Features

- Utilized in depots and back shops

- Detects and isolates intermittent failures in electronics and avionics

- Detects and isolates permanent and intermittent shorts, opens, instability and Electromagnetic Interference (EMI) events

- Rapid set-up with powerful test software

- Quick testing: results displayed real-time

- Easily expandable in 1,280 test point increments

Functions

- Intermittency – detected to less than *50ns on every test point individually, simultaneously and continuously

- Continuity – programmable continuity checks against referenced values

- Log Scope – instant display of a circuits or component’s stability

- Shorts – two modes providing shorts indication and shorts tracing capability

- Analyze – provides an impedance signature for the Unit Under Test

- AutoMap – rapid mapping of circuits for complex and/or ad hoc testing

Benefits

- IFDIS 2.0 eliminates:

- Repeated returns of the same assembly for repair

- Excessive spare part stock to cover units out of service

- Downtime to replace units

- Scrapping costs associated with unrepairable units

- Wasted test time using technology that cannot detect intermittent faults

- Reduces No Fault Found (NFF), Can Not Duplicate (CND), Re-Test OK (RTOK), No Evidence of Failure (NEOF)

- Reduces life-cycle support costs

- Increases operational availability, asset availability, and mission capable rates

- Compliance with US Department of Defense (DoD) MIL-PRF-32516 for electronic test equipment, intermittent fault detection and isolation for chassis and backplane conductive paths

For Pricing and Delivery Information, please call +1 (801) 710-1618

Patented, with additional U.S. and foreign patents pending