Frequently Asked Questions

Frequently Asked Questions

We define an intermittent the same way the Department of Defense (DoD) defines it in MIL-PRF 32516. An intermittent fault is a momentary discontinuity, a malfunction of a device or system that occurs at irregular intervals. The intermittent faults our technology is able to capture are notoriously difficult to identify and repair and are typically categorized as No Fault Found (NFF) due to conventional test equipment’s inability to detect them.

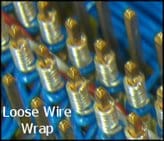

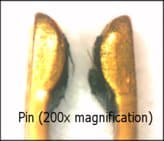

Electrical intermittent faults are a “temporary” deviation from the nominal operating condition of a circuit or device. Common root causes of intermittence are the component interconnecting devices, such as:

- solder joints

- connectors

- cables/wires

- crimps

- splices

- circuit traces

- vertical interconnect accesses (vias)

- wire wraps

- relays

- circuit breakers

- pins

USDoD MIL-PRF 32516 Electronic Test Equipment, Intermittent Fault Detection and Isolation for Chassis and Backplane Conductive Paths

ECIA EIA-364-46 Microsecond Discontinuity Test Procedures for Electrical Connectors, Contacts and Sockets

ECIA EIA-364-87 Nanosecond Event Detection Test Procedure for Electrical Connectors, Contacts and Sockets

- Intermittent Fault Detection capabilities of the IFDIS 2.0 and portable IFD comply with all three specifications

- Department of Defense Industry Week 2016 Competition to assess compliance with USDoD MIL-PRF-32516

- Universal Synaptics ONLY company to pass all tests in compliance with MIL-PRF-32516

- “Short duration intermittent faults that are under 100 nanoseconds across all LRU/WRA backplane circuits and associated wire harnesses”

- IFDIS 2.0 and the portable IFD test for discontinuity across all circuits, simultaneously and continuously, without the need for daisy-chaining circuits or complex Interface Test Adapters (ITAs)

- Unique capability to isolate a fault to a specific circuit without further ‘splitting of the system’

- Monitor all circuits at the same time without the need for loop resistance test

- Provides 100% test coverage while detecting interruptions of circuit continuity of less than 50nsec for resistance of 1-10 Ohms (depending on the total resistance of each of the individual circuits under test)

- Exceeds the requirements of EIA-364-46B

- Meets the requirements of EIA-364-87 (Test Condition F, 50nsec)

- Both test requirements can be carried out at the same time without any compromise to either requirement

- Portable IFD capability: up to 512 individual circuits/test points can be simultaneously tested/monitored

- IFDIS 2.0 capability: unlimited individual circuits/test points can be simultaneously tested/monitored

The portable IFD monitors all circuits or wires under test simultaneously and continuously while traditional wire test sets (automatic or manual) scan and sample one circuit or one wire at a time even when connected to multiple wires. A point-to-point tester that serially scans through the circuitry of a Unit Under Test (UUT), cannot detect and isolate an intermittent event that is random in time, place, amplitude, and duration. The portable IFD is similar to having a latching oscilloscope monitor every circuit, wire, or test point of a UUT all set to latch and report the precise location of each intermittent fault.

Related Articles:

Continuous Circuit Monitoring – A Dramatic Shift in Electronics Testing

Simultaneous & Continuous Testing (PIFD) vs. Scanning / Sampling Testing (AWTS)

No, the core intermittent fault technology is exactly the same, however the product delivery is different. IFDIS 2.0 utilizes a simulated operational environment to test electronic components. The IFD is a portable solution used to test for intermittent faults within Electronic Wiring Interconnect Systems (EWIS) and harnesses.

Prior to the development of the IFD, Intermittent Fault Detection technology, testing all lines, at the same time, simultaneously and continuously, was not really possible to any efficient degree using conventional test technology. The only way to comprehensively detect the low-level intermittence causing No Fault Found (NFF) is to test all of the lines, at the same time, simultaneously and continuously. The sensing technology also has to be super-sensitive on each of the individual lines to pick up the developing intermittent problems. Having significant experience and interest in the science of Artificial Intelligence (AI), our company’s founders felt the most analogous solution to this testing dilemma would be to mimic the parallel distributed processing operation found in the operation of the human brain and sensors of the body’s nervous system. The resulting IFD and its current derivatives, the IFDIS 2.0 and portable IFD share a common intermittence testing architecture that comprises a hardware Neural Network

Related Articles:

Continuous Circuit Monitoring – A Dramatic Shift in Electronics Testing

Simultaneous & Continuous Testing (PIFD) vs. Scanning / Sampling Testing (AWTS)

The IFDIS 2.0 is very simple to program and set up. A training course is available from technician to board room executive tailored specifically to the client’s abilities and current knowledge / experience. Training courses range from data acquisition and analysis to the design and development of the interface as well as the programming of the IFDIS 2.0, with a focus on troubleshooting, reading and understanding the IFDIS 2.0 test results.